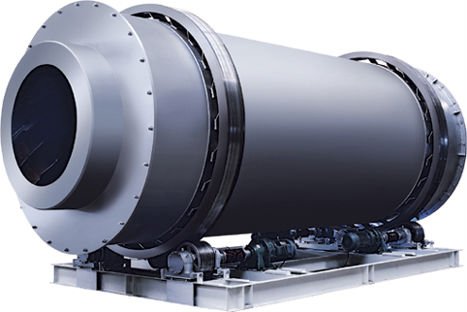

Photos of Three drum rotary dryer

Technical Parameter of Three drum rotary dryer

Model(m) |

2x4 |

2x4.5 |

2.2x5 |

2.5x6 |

2.7x6.5 |

3.0x6.5 |

3.2x7 |

3.6x8 |

4.2x8 |

Diameter of outer cylinder(m) |

2 |

2 |

2.2 |

2.5 |

2.7 |

3 |

3.2 |

3.6 |

4.2 |

Length of outer cylinder (m) |

4 |

4.5 |

5 |

6 |

6.5 |

6.5 |

7 |

8 |

8 |

Cylinder volume (m3) |

13.5 |

14.13 |

18.99 |

29.43 |

37.19 |

45.92 |

56.27 |

81.39 |

110.78 |

Cylinder speed (r/min) |

4-10 |

4-10 |

4-10 |

4-10 |

4-10 |

4-10 |

4-10 |

4-10 |

4-10 |

Max. inlet temperature (degrees centigrade) |

700-750 |

700-750 |

700-750 |

700-750 |

700-750 |

700-750 |

700-750 |

700-750 |

700-750 |

Capacity (t/h) |

12-16 |

13-18 |

15-23 |

20-28 |

24-33 |

35-40 |

40-60 |

55-75 |

70-120 |

Motor power (kw) |

5.5x2 |

5.5x2 |

7.5x2 |

5.5x4 |

7.5x4 |

11x4 |

15x4 |

18.5x4 |

22x4 |

Introduction and Structure of Three drum rotary dryer

This three drum rotary dryer, also called triple way dryer,three cylinder roasting machine,three layer drum dryer. It's a kind of energy saving dryer/roaster, with the advantages of small space occupied.

The Applicable Scope of Three-cylinder Roaster/dryer:Energy-saving three-layer rotary drum drying machine is a kind of energy saving effiency improvement dry equipment ,on the basic of original materials and humidity dryer conducted .through constantly improvement , has reached the international advanced level ,not only can handle viscous lower high moisture material , can handle viscous larger high mosture materials.this machine is suitable for various kinds of water cut less than 85%of dry slag materials worse .such as beer worse ,alcohol worse ,fruit dreg ,liquid ,sauce worse ,sugar residue ,starch slag ,livestock waste ,and slaughtering scraps ,etc ,for opening feed resources , reduce keeping costs , and reduce environmental pollution has good effect . The actual tons of dry material consumption toreduce 220kg coal by the beer bad drying manufacturers use .

The Structure and Working Principle of Three-cylinder Roaster/dryer:

The material is servicer into rotary roller ,to realize the lining of the regime of drying , the copy plate inner material constantly start to copy , Scatter a spiral heat marching type, material mobile to realize the other side of the lining, into the middle counter-flow drying , Material in the middle are constantly repeated Yang into, show into two steps forward and one step back, materials in a way of going already fully absorb the middle inner drum and absorbs heat release, the quantity of heat of middle roller, and extended the drying time, material in this achieve best dry condition.Materials on the other end and middle step into outer , material in outer roller inside a rectangular multi-loop travel ,achiece the materials in a hot air drying effect under the action of discharge rollers ,quick trip , Not reached the wet materials dry effect because of self-respect and cannot fast progression, material in the rectangular copy plate, which fully dry in complete drying purpose.

The Three-cylinder Roaster/dryer has two big advantages:

1. Under the condition of the same output ,three-layer roasting owns small space occupied ,easy transport , installation is convenient

2. Heat fully :material and hot air is downstream and upstream ,downstream on reciprocating crossover realize heat ,heat time long ,materials evaporate eduction of moisture in inner drum ,directly by fan siphoned off ,heat utilization efficiency

3. Internal copy plate once damaged ,maintenance great unconvenience

Main features of Three drum rotary dryer

Main features:

1.simple design,self-insulation,improve the heat efficiency to exceed80%.

2.refined experience ,stable operation.

3.good drying performance,coal consumtion less than 8kg when drying material

4.the fuel can be coal,oil,natural gas etc,dry mass,granule and powder material.

5.reduce land area for 50% compared to single drum rotary dryer,so construction investment is rsaved for 50% ,power consumption to saved 60%.

6.finished product moisture can be adjusted depends on requirement of client.

7.lower outlet tempreture ,longer dust removal using life.

8.drive by tug not geat and pinion.

9.finished product tempreture lower than 60°,packing can be done continuously.

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.