Technical Parameter of Mesh Belt Dryer

KHWD 6 |

KHWD 8 |

KHWD 10 |

KHWD 12 |

KHJWD 16 |

KHWD 20 |

KHWD 24 |

KHWD 30 |

|

width of Net belt (mm) |

600 |

800 |

1000 |

1200 |

1600 |

2000 |

2400 |

3000 |

Length of drying section(m) |

6-12 |

6-12 |

6-16 |

8-16 |

8-22 |

10-26 |

12-30 |

12-40 |

Length of feeding section(m) |

1 |

1 |

1 |

1 |

1 |

1.5 |

1.5 |

2 |

Length of transmitting section(m) |

1 |

1 |

1 |

1 |

1 |

1.5 |

1.5 |

2 |

Drying area (m2) |

3.6-36 |

4.8-48 |

6-80 |

7.2-96 |

12.8-105.6 |

20-260 |

28.8-360 |

36-600 |

Unit mumber |

1-5 |

|||||||

Interlamellar spacing (mm) |

400-600 |

|||||||

Carrying capacity |

90-200 Kg/m2 |

|||||||

Operation temperature (°C) |

carbon steel≤400 C°,stainless steel≤600 C° |

|||||||

Drying strength ((kgH2O/h) |

5-20kg H2O/m2.h |

|||||||

heat source |

hot wind、electricity、steam |

|||||||

Running speed |

0.06-1m/min |

|||||||

Transmission powder(kw) |

1.1-2.2 |

1.1-2.2 |

1.1-2.2 |

1.1-3 |

1.5-3 |

1.5-4 |

3-7.5 |

5-11 |

Matching equipment |

conveying equipment、air heating furnace、dust removing equipment、draught fan etc. |

|||||||

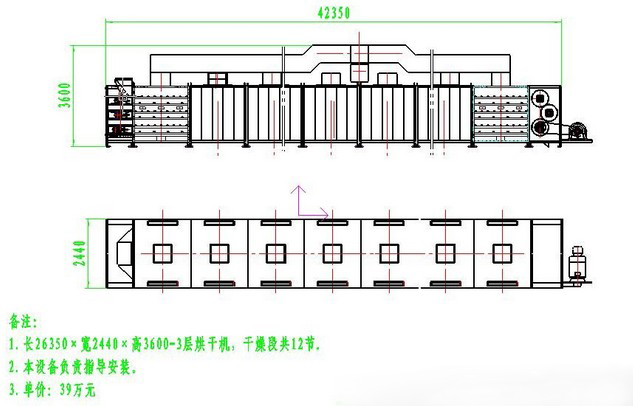

Operation principle and Application of Mesh Belt Dryer

Mesh belt dryer is a kind of batch, continuous production drying equipment, mainly for better ventilation sheet, strip, granular materials, such as: preserved fruit, pepper, potato chips, ball games, grain straw, wood, etc., the main heating electric heating, steam heating, hot air heating.

De-watering vegetable, particle feed, gourmet powder, shredded coconut stuffing, organic pigments, compound rubber, acral fibre, medicine product, medicine material, small wooden product, plastic product, aging and soli.

Advantages:

1). small space to take

2). low investment

3). high efficinency

4). large output and high evaporation strength

5). standardized production; the number of segments can be increased according to the output

Working Principle of Mesh Belt Dryer

materials are uniformly put on the mesh-belt by the feeder. The mesh-belt uses generally 12-60 mesh stainless steel wire net and it is drawn and moved inside the drier by a transmission device. The drier is composed of several units. For each unit, the hot air is circulated separately. Some exhausted gas is discharged with a special moisture elimination blower. The waste gas is controlled through an adjustment valve. The hot air passes through the mesh-belt covered with the material from the top to the bottom or from the bottom to the top and this will complete the heat and mass transfer process. This process will bring the material water away. The mesh-belt moves slowly, Running speed can be freely adjusted according to the material temperature. The final products after the drying will fall into the material collector continuously. The top and low circulation units can be freely equipped according to the users’ demand. The unit number can be selected according to the demand.

small footprint, small investment, high efficiency,high-yield, high evaporation intensity, standardization of production, production increased according to the number of segments dification for the electronic component and device,

Why choose us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Winnermac Mining Machinery Manufactory are made by ourselves, with lower price, good quality.

2. Full and perfect service

♥.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design

and manufacturer equipment according to your special demand.

♥.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you

♥.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

3. Product Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc.

4. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demand.

Over 26 years experience in this field

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.