Technical Parameter of Flyash rotary dryer

Specification(m) |

Capacity (t/h) |

Motor power (kw) |

Moisture (%) |

Calorific value of coal (kcal/kg) |

Moisture (%) |

Φ1.8 *18 |

7-10 |

11 |

20±5 |

≥5500 |

≤3 |

Φ2.0*18 |

10-12 |

15 |

20±5 |

≥5500 |

≤3 |

Φ2.2*20 |

12-15 |

18.5 |

20±5 |

≥5500 |

≤3 |

Φ2.4*20 |

15-25 |

22 |

20±5 |

≥5500 |

≤3 |

Φ2.6*20 |

25-30 |

30 |

20±5 |

≥5500 |

≤3 |

Φ2.6*20 |

30-40 |

55 |

20±5 |

≥5500 |

≤3 |

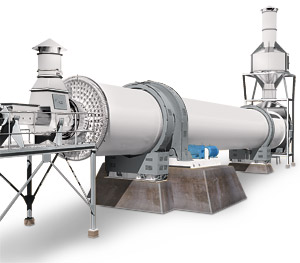

Brief introduction of Flyash rotary dryer

Fly ash dryer machine is designed according to the features of fly ash which the moisture is higher than other materials; the proportion is lower than other materials, big flow ability in the drying process. It has features of compact structure, less location area, reliable work, low energy consumption, high thermal efficiency, good drying effect, easy to realize automation control, save operators.

Flyash dryer applies to dry flyash, phosphorous gesso and titanium

gypsum and other industry dust, its working principle as follow: powder

or granular flyash by belt conveyor to feeder, again by feeder put

flyash conveying to dry roller inside, flyash in dry roller flipped by

distributive copy plate device,ash in roller terminal is discharged by

discharger, transported by the belt conveyor and the dried output

drying process is completed.

Coal slime dryer's working principle:

The powder and granular fly ash is sent to the feeder by belt feeding machine, then transport from feeding machine to drying drum, the fly ash is stirred by shoveling plate in the drying drum, even disperse to make fully contacting with hot air, to reach the goal of transferring heat for drying. At last the fly ash finished products is sent out through the discharging machine in the end of drum, then through the belt discharging to arrive the finished products area, complete the whole drying process.

Main features of Flyash rotary dryer

Main features:

1. The investment required is 1/6 of the imported products

2. It will ensure you the final material a moisture below 0.5% which is the first product of ash and slag product line

3. Cylinder self-insulation thermal efficiency as high as 80% (traditional monocular dryer thermal efficiency was only 35%) to improve thermal efficiency of 45%

4. Fuel, kerosene vapor applicable, 20mm below the block to dry powder material feed pellets

5. Dryer than the monocular area of about 50% reduction, 50% reduction in civil engineering, power consumption decreased to 60%.

6. Use and manufacture than ordinary steel, alloy steel wear plate 4 times

7. Can be customized easily control the required final moisture indicator

8. Outlet temperature is low, dust removal device a long time

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.