Brief Introduction of Vertical Crusher :

Vertical Crusher also called vertical mill, which is one advanced mill, adopting top technology domesic and abroad, and based on many years' mill experiences. It can crush, dry, grind, and classify the materials. vertical milling machine can be widely used in such industries as cement, power, metallurgy, chemical industry, non-metallic mineral. It is used to grind granular and powdered materials into powder with required fineness

| Price: | negociable |

| Brand Name: | King State |

| MOQ: | 1 Set |

| Payment Terms | T/T,L/C |

| Delivery Time: | 10-15 days |

| Shipping Port | Tianjin/Qingdao/Shanghai |

| Certification | ISO2000,SGS |

Technical parameter of Vertical Crusher :

| Model | Major Axis Speed (r/min) |

Max Feed Size (mm) |

Antispates a grain of Degree (mm) |

Processing Capacity (t/h) |

Motor Power (kw) |

Weight (kg) |

Overall Dimmensions (mm) |

| PLFX-750 | 1100 | 70 | 0-10 | 10-25 | 37 | 4000 | 2349×1150×1660 |

| PLFX-1000 | 980 | 80 | 0-10 | 15-35 | 55 | 6100 | 2838×1500×1800 |

| PLFX-1250 | 780-1030 | 100 | 0-10 | 35-60 | 75-90 | 9880 | 3000×1670×2216 |

| PLFX-1500 | 650 | 120 | 0-10 | 50-70 | 132 | 13700 | 4248×2100×2250 |

| PLFX-1750 | 560 | 140 | 0-10 | 70-85 | 160 | 18500 | 4930×2370×2553 |

Application of Vertical Crusher

King State Vertical Crusher is widely applicable to the industrids such moulded coal,foundry,refractiries,building mat-erial,condtuction,chemical industry and metallurgy etc.Because of the convenient operation and repairs ,low power expenditure, high efficiency and whole-mac-hinetransport, it is the idealupd-ated product for rolling and stirring in each industry.

Advantages of Vertical Crusher

1. Low Investment Cost

This Vertical crusher itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system. In addition, it can be installed outside, so it will reduce a large number of investment costs.

2. Low Operation Cost

High efficiency: roller compacted materials directly onto the grinding disc, so power consumption is low. Compared with ball mill, it saves energy consumption by 30% ~ 40%. Less wear and tear: As the roller is not in direct contact with the disc, and material of the roller and liner is high quality, so life lime is long.

3. High Drying Ability

As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with diffirent humidity.

4. Simple and reliable operation

It is equipped with automatic control systems, so remote control makes it easy to operate. It is equipmented with one device,which prevents the roller from contacting with the liner directly, and avoids the destructive impact and severe vibration

5. the stability of product quality

As the material stays in the mill for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.

6. Maintenance convenience

By reparinging fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime

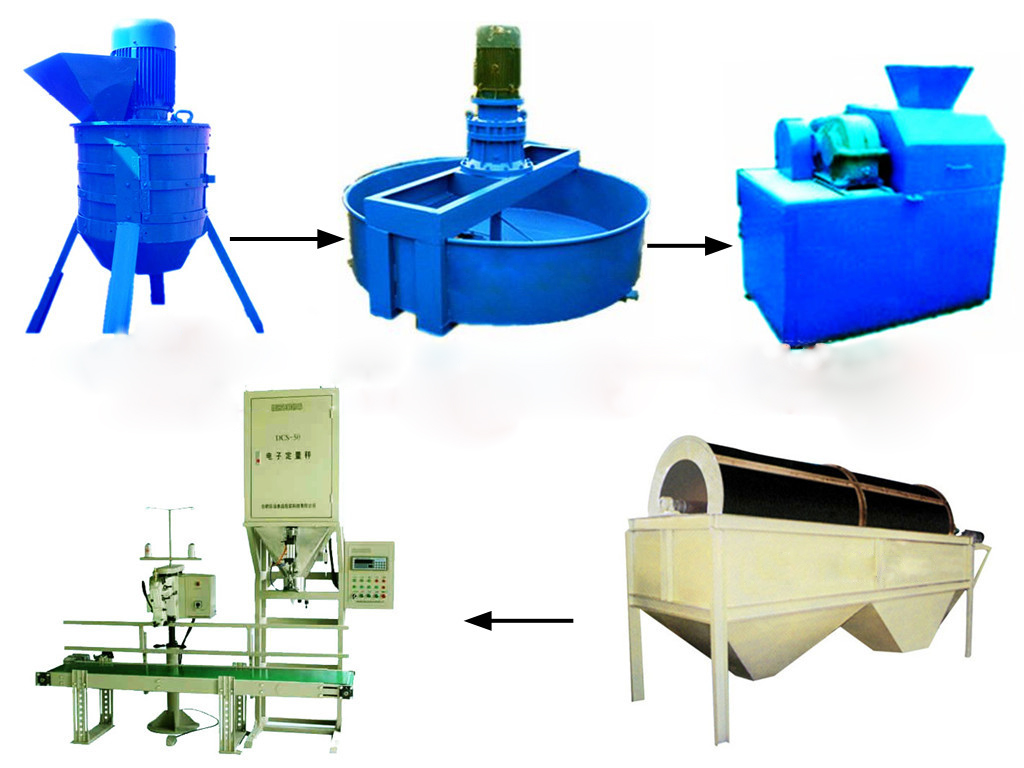

Our Company is a professional manufacturer and supplier of fertilizer Machine,fertilizer vertical crusher,formula fertilizer blending machinery, fertilizer mixing machine and soluble fertilizer machine, and automatic production line for fertilizer, we also have many other products, such as Micro element compound fertilizer Production line and organic fertilizer production line.

OurCooperation/ Exported Countries

※ Indonesia ※

※ Indonesia ※

NPK compound fertilizer production line with capacity 50,000tons per year in 2010

NPK compound fertilizer production line with capacity 20,000tons per year in 2011;

NPK compound fertilizer production line with capacity 100,000tons per year in 2012

Organic fertilizer production line with capacity 50,000tons per year in 2013.

※ Egypt ※

Compound fertilizer production line with capacity 30,000tons per year in 2009

Compound fertilizer production line with capacity 80,000tons per year in 2010;

※ Nigeria ※

Compound fertilizer production line with capacity 30,000tons per year in 2010.

※ Mauritius ※

NPK compound fertilizer production line with capacity 50,000tons per year in 2010,

※ Vietnam ※

Compound fertilizer production line with capacity 20,000tons per year in 2009,

Most of our old clients have purchased or been planning to purchase a second production line to enlarge the manufacturing capacity owing to our good quality and best after-sales service .We have been relying on high-quality products, advanced technology, reasonable price, and good after-sales service to meet the requirements of all the users.

Why choose us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Winnermac Mining Machinery Manufactory are made by ourselves, with lower price, good quality.

2. Full and perfect service

♥.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design

and manufacturer equipment according to your special demand.

♥.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you

♥.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

3. Product Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc.

4. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demand.

Over 26 years experience in this field

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.