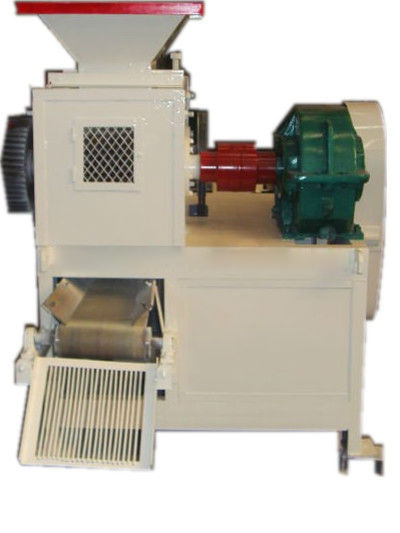

Photos of Inorganic Fertilizer Machine

Introduction of Inorganic Fertilizer Machine(Production Line)

Inorganic fertilizer machine commonly be kown as double roller granulator,it is especially be designed to product inorganic fertilizer at the first time. nowadays, also can used to produce organic fertilizer by using mositure less than 10% organic materials. It is multifunctional fertilizer press machine, this fertilizer roller press granulator can make compound fertilizr but also can make organic fertilizer granules.it is multifunctional,but the finished granules are oval shapes. you can use a ball shaping machine to make it into round granules, Which is developed by our own company. Production only needs room temperature without drying machine, which can save a lot of energy and cost, the roller press granulator production yield is 0.5-1t / h,1-1.5t / h,and 1.5-2t/h. if you want to use disc granulator,that is also best machine for organic fertilizers.

Specification of Inorganic Fertilizer Machine:

Model |

FGZL—1 |

FGZL—1.5 |

FGZL—2 |

|

Capacity |

0.5—1t/h |

1—1.5t/h |

1.5—2t/h |

|

granulation rate |

≥85% |

≥85% |

≥85% |

|

Power |

15kw |

18.5kw |

22kw |

|

Material moisture content |

Max 15% |

|||

Gramulation temperature |

Constant temperature |

|||

pellet |

Diameter |

3—15(mm) |

||

Strength |

6—20N(resistance to crush force) |

|||

Shape |

oval |

|||

Name Spec |

Vertital granulating pelletlizing machine |

Environment extrusion granulator machine |

Double-roller granulator mahcine |

|||

Model |

FZLJ01 |

FZLJ02 |

FHKJ25 |

FHKJ30 |

FDZJ-15 |

FDZJ-30 |

Output size(mm) |

Φ3-Φ6 |

Φ4-Φ6 |

Φ2-Φ6 |

Φ2.5-Φ6 |

Φ3.2-Φ6 |

Φ4-Φ8 |

Power(kw) |

30 |

55 |

15 |

22 |

15 |

30 |

Capacity(T/h) |

1.2-2.5 |

2-4 |

0.7-1.5 |

1.2-2 |

1-1.5 |

3-5 |

Features of Inorganic Fertilizer Production Line

1. Saving energy, low consume

With the normal temperature,granulating the raw material, compare with other ways, no need oil, gas to dry.

2. No need binder

In domestic, compound fertilizer always adopt steam granulating. The steam is coagulating in the raw material, after coagulating, as the brinder function.

3. Invest lower, the flow chart process is simple.

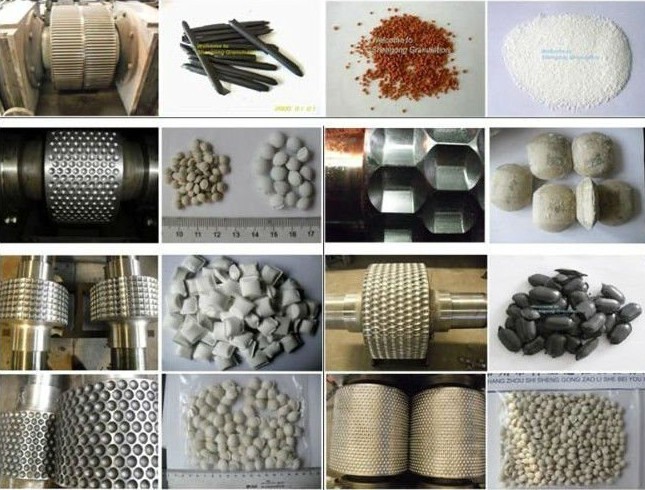

4. Fit to different raw material, as far, the guanulating machine has successfully used to pelletting more that 20 series raw material, like: ammonium nitrate,carbamide,ammonium chloride,lime nitrate,potassium chloride,potassium sulfate and so on.Besides,adopt the graunlating process,can produce difference products with one set equipments.

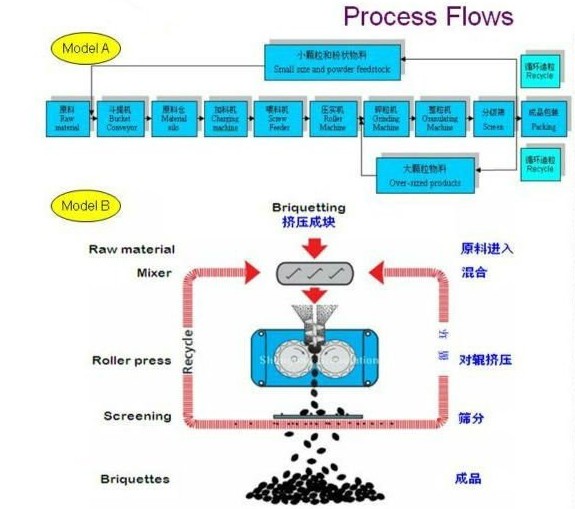

Working Process of Inorganic Fertilizer Production Line

The series of fertilizer press machine is extrusion -slip model , its working principle is the belt and pulley driven by electric motors , to the driving shaft to pass through the reducer , and synchronization off the gear and the driven shaft opposite the work . Material from the hopper into the granulating room of the roller press granulator, after the roll extrusion molding , mold release , making the ball , and after a chain sent to the broken screen studio , under the screen and the separation of the finished pieces (the ball) tablets , and then returning the mixture of material with new material . With the roller extrusion granulator continuous rotation of motor , the material continues to enter in order to achieve mass production .

this roller press granulator has two main working parts:1.squeezing and pressing part: materials are pressed into big high density and hard cake,under the squeezing pressure.2.granulating part:the press cake is crushed and screened into small granules.

The roller extrusion granulator has Wide adaptability of raw materials is DAP,SSP,GYPSUM,SHEEP MANURE, COW MANURE , chicken manure, pig manure,bentonite and other animal poultry manure waste and so on.the roller press granulator Production rate is high. It can produce all kinds of high concentration with a various fertilizers including organic fertilizer, Inorganic fertilizer,compound fertilizer,etc.especially rare earth fertilizer,potash fertilizer,ammonium bicarbonate series for this fertilizer granulator.the fertilizer press machine makes up the gap leading the position in domestic.when using this granulator as a whole fertilizer production line,it does not need a rotary dryer.

Technical data of Ball Shaping Machine

Model:PY--I

Model:PY--I

power:5.5kw

capacity:800--1000kg/h

size:900X900X1200MM

PY--II

power:4+4kw

capacity:2--3t/h

size:1800X900X1450MM

Advantages of Inorganic Fertilizer Machine

1. Equipped with advanced fertilizer manufacturing technique, this fertilizer production line can finish fertilizer granulation in one process.

2. Adopts advanced rotary drum granulator, granulating ratio is up to 70%, high intensity of granules,

3. The inner cylinder body adopts high quality rubber plate lining structure which prevents the raw material from sticking on the plate.

4. Wide adaptability of raw materials, suitable for compound fertilizer, pharmaceuticals, chemicals, fodder and so on.

5. High-quality, stable performance, anti-corrosion and wear-resistant materials components, abrasion proof, low energy consumption, long service lifespan, easy maintenance and operation, etc.

6. High efficiency and economic returns, and the small part of feeding back material can be granulated again.

7. Adjustable capacity according to customers’ requirements.

Why choose us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Winnermac Mining Machinery Manufactory are made by ourselves, with lower price, good quality.

2. Full and perfect service

♥.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design

and manufacturer equipment according to your special demand.

♥.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you

♥.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

3. Product Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc.

4. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demand.

Over 26 years experience in this field

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.