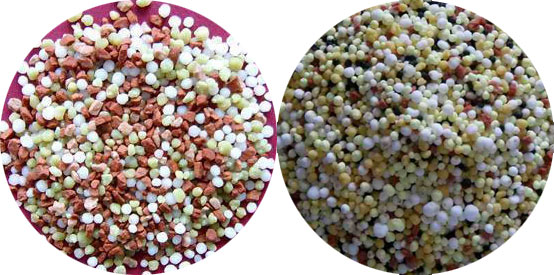

Photos of BB Fertilizer Machine

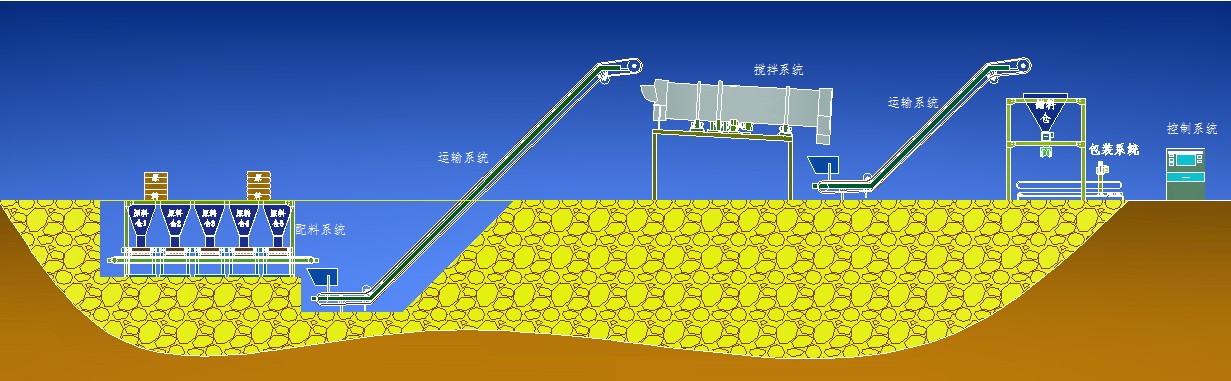

Introduction of BB Fertilizer Machine(Production Line)

BB fertilizer machine, we also call it bulk blending fertilizer machinery, formula fertilizer machinery around the world.It is automatic machine for kinds of material batching, mixing and packing. The market commen name is bulk blending fertilizer equipment, fertilizer mixing equipment.we are real famous fertilizer production machinery manufacturer in China. We supply BB fertilizer (bulk blending fertilizer or bulk blended fertilizer) machinery, formula fertilizer machinery, fertilizer mixing machinery and water soluble fertilizer machinery.

Technical parameter of our BB fertilizer machine:

1.Packing: 10-50 kg /bag

2,.Capacity: 5-10 ton/hour

3.Kinds of raw material: 5

4.Packing precision: ≤±0.2%

5.Batching precision: ≤±0.2%

6.Available frame outer dimensions: Length: 1350mm width: 300mm height: 500mm 7.Dimension of pit: length: 400-500mm width: 300mm depth: 200mm

8.Power: 15kw for complete plant; 0.3-0.5 degree/ton

9.Operators: 2-4 persons (except the process of conveying for raw material and end product) 10.Material: Stainless steel (304 National Standard)

1.Packing: 25-50 kg /bag (can accord customer’s requirement)

2.Capacity: 10-15 ton/hour

3.Packing precision: ≤±0.2%

4.Batching precision: ≤±0.2%

5.Available frame outer dimensions:

6.Power: 15kw for complete plant; 0.3-0.5 degree/ton

7.Operators:

4-5 persons (except the process of conveying for raw material and end product) 8.Material: Stainless steel (304 National Standard) 9.Sieving powder out automatically, guarantee 100% granular fertilizer.

1.Dynamic batching and continuous mixing.

2.Production capacity: 30-40 ton/hour

3.Batching capacity: 30-40 ton/hour; batching precision : ≤±0.5%(meet the latest national standard of BB fertilizer)

4.Kinds of raw material: 3-12

5.Packing: 25kg/bag 40kg/bag 50kg/bag (can be made according to customer’s requirement)

6.Packing precision: ≤±0.2

7.Intergradient way: contentious batching and mixing;

8.Process staff(person): 5-7(except process of raw material and end product conveying) 9.Material: industrial stainless steel (304 National Standard)

10.Mixing form: roller-type mixing machine (automatic sieving)

11.Lifting form: Belt conveyor with big tilt angle or bucket elevator

12.Clip bag controlled by machine hand automatically

13.Machine hand make the stacking automatically

Packing detail (kg/bag) |

Hourly capacity (bag/h) |

Minute capacity (bag/M) |

Annual capacity (t/year) |

Type of packing machine |

Numbers of packing machine (Set) |

50 kg/bag |

1000 bags |

17 bags |

300000 t/year |

Single hopper |

2sets |

40 kg/bag |

1250 bags |

21 bags |

300000 t/year |

Double hopper |

2sets |

25 kg/bag |

1600 bags |

34 bags |

300000 t/year |

Double hopper |

2sets |

Advantages of BB Fertilizer Machine

1. High batching precision: study of reproduction technology overcomes the negative effect to the batching accuracy that is caused by the difference of proportion and unit weight, and the quality of product is guaranteed.

2. High production efficiency: the redesign of material feeding equipment realizes the successively dynamic measurement, which can completely meet customers need.

3. High quality: stainless steel is used in the place where batching system and material contact. Such components as electric control system and gauge, etc. all have been disposed by sealing in order to avoid corrosion by fertilizer and prolong its lifespan. The use of flow controller makes the structure more compact and firm, as well as the system runs fluently.

Working Process of BB Fertilizer Production Line

PLC control system → Auto proportion ingredient by belt scale → transfer by belt conveyor → continuous mixing → transfer by belt conveyor → automatic ration packing machine→ edge fold and stitching → end product storage

Our Company is a professional manufacturer and supplier of BB fertilizer Machine, formula fertilizer blending machinery, fertilizer mixing machine and soluble fertilizer machine, and automatic production line for fertilizer, we also have many other products, such as Micro element compound fertilizer Production line and organic fertilizer production line.

Our products not only cover the domestic market but also are exported to other countries such as Korea, North Korea, and Kazakhstan etc. Moreover, we have received good comments from both home and abroad. The products have established a splendid brand image in both society and customers, and have been reported on many newspapers. As a famous enterprise, our corporation was the first corporation that has passed “ISO9001” among the same industries, as well as a series of state-level tests. Our corporation is a well-known company in the field of fertilizer machine production and also the head in terms of technology and service.We always believe in Customer satisfaction. Our products are known for their quality and durability.

Our products not only cover the domestic market but also are exported to other countries such as Korea, North Korea, and Kazakhstan etc. Moreover, we have received good comments from both home and abroad. The products have established a splendid brand image in both society and customers, and have been reported on many newspapers. As a famous enterprise, our corporation was the first corporation that has passed “ISO9001” among the same industries, as well as a series of state-level tests. Our corporation is a well-known company in the field of fertilizer machine production and also the head in terms of technology and service.We always believe in Customer satisfaction. Our products are known for their quality and durability.

If you are interested, please do not hesitate to contact me for more information, and at the same time we hope to set up a long-term business relationship with your esteemed company.

OurCooperation/ Exported Countries

※ Indonesia ※

※ Indonesia ※

NPK compound fertilizer production line with capacity 50,000tons per year in 2010

NPK compound fertilizer production line with capacity 20,000tons per year in 2011;

NPK compound fertilizer production line with capacity 100,000tons per year in 2012

Organic fertilizer production line with capacity 50,000tons per year in 2013.

※ Egypt ※

Compound fertilizer production line with capacity 30,000tons per year in 2009

Compound fertilizer production line with capacity 80,000tons per year in 2010;

※ Nigeria ※

Compound fertilizer production line with capacity 30,000tons per year in 2010.

※ Mauritius ※

NPK compound fertilizer production line with capacity 50,000tons per year in 2010,

※ Vietnam ※

Compound fertilizer production line with capacity 20,000tons per year in 2009,

Most of our old clients have purchased or been planning to purchase a second production line to enlarge the manufacturing capacity owing to our good quality and best after-sales service .We have been relying on high-quality products, advanced technology, reasonable price, and good after-sales service to meet the requirements of all the users.

Features of BB Fertilizer Machine

1.Batching system adopts the latest core component of static batching control of worldwide.

2.Special feeding system adopted for ensuring smooth feeding process.

3,Batcher scale makes accurate batching with static batching mode, which is suitable for capacity ≤3ton per hour.

4.Two methods of feeding: Belt conveyor (advantage: anticorrosion and long working life, easy to maintain, lower failure rate, convenient clearing; disadvantage: longer cover area); hopper elevator (advantage: cover small area because of its vertical state; disadvantage: not easy to maintain and clean, a little bit of leaking of bottom hopper).

5.We choose new mixing technology for more sufficient and uniform mixing, also shortening the mixing time, which has gained national patent.

6.The control gauge of packing scale reaches the accuracy of 0.1% which can ensure maximization of profit for fertilizer manufacturer.

7.To meet your different levels of service needs, our company has a period of 12 months Warranty Policy and Return Policy and provides free service training to technical personnel.

8.In consideration of the corrosivity of chemical fertilizer, we choose stainless steel as our material of machine, which is thick, solid and long life.

Why choose us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Winnermac Mining Machinery Manufactory are made by ourselves, with lower price, good quality.

2. Full and perfect service

♥.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design

and manufacturer equipment according to your special demand.

♥.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you

♥.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

3. Product Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc.

4. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demand.

Over 26 years experience in this field

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.