Photos of Organic Fertilizer Machine

Introduction of Organic Fertilizer Machine(Production Line)

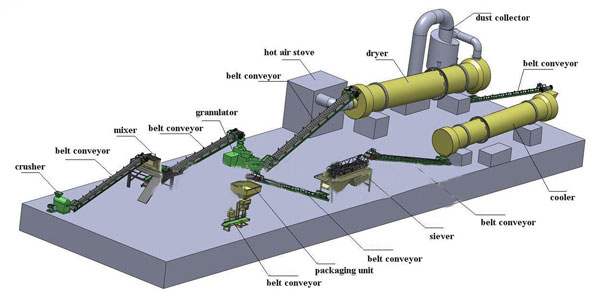

The organic fertilizer machines are: animal manure fermenting machine, high moisture crusher,vertical crusher, chain crusher,vertical mixer,pan mixer, roller granulator,pan granulator, pelletizer, rotary dryer, rotary drum screen, rotary cooler,packing machine, bucket elevator, this organice fertilizer production line is commonly used to process different fermented organic substance into bio-organic fertilizer. It adopts one-step molding technology. Agricultural waste and animal manure are recycled as the main raw materials, thus animal manure or municipal waste is not only creating economic benefits for the enterprise, but also making a great contribution to environmental projects for mankind.

Raw Materials, Which can be used to produce Organic Fertilizer:

1. Agricultural waste: cotton dregs, straw, dregs of beans,rice bran, etc.

2. Animal manure/faeces: mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.

3. Industrial waste: manioc waste, sugar scum, wine lees, vinegar residue, furfural residue, etc.

4. Home scrap: the roots,food waste, and leaves of vegetables, etc.

5. Sludge: the sludge of the river, sewer, etc.

Features of Organic Fertilizer Production Line

1. The line takes animal manure and agricultural waste as its main material, not only turns the waste into valuable things, but also protects the environment.

2. The whole fertilizer production process is centralized controlled, so this series of fertilizer machines are highly automatic and easy to operate.

3. Both batching system and packing system are controlled by the computer, thus ensuring the precision of material batching and fertilizer packing.

4. High-quality, stable performance, compact process layout, advanced technology, and convenient maintenance.

Working Process of Organic Fertilizer Production Line

Organic fertilizer production line is a complete set of equipment from raw materials collection to the organic fertilizer packing.

※ Organic materials fermentation process plays the preliminary but indispensable role in the whole production line. Two main types of compost turner are widely used to turn and mix the compost and accelerate the fermentation speed: Self-propelled compost turner and hydraulic compost turner.

※ Crushing Process: The compost lump materials should be grinded before the granulating process. But we can leave out crushing process when the compost material is fine enough. Vertical chain crusher and double-shaft horizontal crusher, two types of crushing machine can be used to crush lump compost fertilizer raw materials.

※ In the Mixing Process, two types of mixing machine are applied to mix raw materials in the fertilizer production line: horizontal mixer and vertical mixer.

※ Drying process. When granulating, the moisture of fertilizer raw materials should be less than 25%, so we should dry the raw materials if the moisture is more than 25%. Rotary drum drying machine is mainly used for drying the fertilizer with a certain degree of humidity and particle size.

※ Drying process. When granulating, the moisture of fertilizer raw materials should be less than 25%, so we should dry the raw materials if the moisture is more than 25%. Rotary drum drying machine is mainly used for drying the fertilizer with a certain degree of humidity and particle size.

※ Then is the Granulator Process. Granulating process is the core part in this production line, so we choose the suitable model of fertilizer granulator according to customers detailed requirements. Disc granulator machine can be chosen to granulate the materials evenly.

※ Rotary Drum Cooling Machine is used for cooling fertilizer to make fertilizer particles stronger.

※ Rotary drum screening machine is used to separate the granules from the large particles which need to be returned for the second crushing and granulating. Rotary drum coating machine is used to coat the fertilizer and prevent the fertilizer from sticking together.

※ Rotary Drum Cooling Machine is used for cooling fertilizer to make fertilizer particles stronger.

※ Rotary drum screening machine is used to separate the granules from the large particles which need to be returned for the second crushing and granulating. Rotary drum coating machine is used to coat the fertilizer and prevent the fertilizer from sticking together.

※ The last process is packaging process. Fertilizer packaging machine can package bags quantitatively and automatically. We also need some auxiliary equipment for connection such as belt conveyor, bucket elevator, etc.

Advantages of Organic Fertilizer Machine

1. Equipped with advanced fertilizer manufacturing technique, this fertilizer production line can finish fertilizer granulation in one process.

2. Adopts advanced rotary drum granulator, granulating ratio is up to 70%, high intensity of granules,

3. The inner cylinder body adopts high quality rubber plate lining structure which prevents the raw material from sticking on the plate.

4. Wide adaptability of raw materials, suitable for compound fertilizer, pharmaceuticals, chemicals, fodder and so on.

5. High-quality, stable performance, anti-corrosion and wear-resistant materials components, abrasion proof, low energy consumption, long service lifespan, easy maintenance and operation, etc.

6. High efficiency and economic returns, and the small part of feeding back material can be granulated again.

7. Adjustable capacity according to customers’ requirements.

Why choose us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Winnermac Mining Machinery Manufactory are made by ourselves, with lower price, good quality.

2. Full and perfect service

♥.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design

and manufacturer equipment according to your special demand.

♥.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you

♥.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

3. Product Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc.

4. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demand.

Over 26 years experience in this field

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.