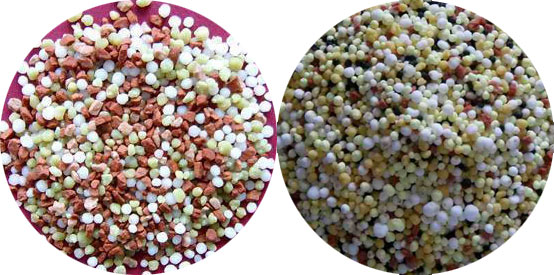

Photos of Rotary Drum Granulator

Brief Introduction of Rotary Drum Granulator :

Rotary Drum Granulator is the key equipment in compound fertilizer industry. And it can be used in cold and heat granulation as well as large-scale production of compound fertilizers, which is of high, medium, or low concentration. This granulator can be used in conjunction with other fertilizer equipment, or used individually.

| Price: | negociable |

| Brand Name: | King State |

| MOQ: | 1 Set |

| Payment Terms | T/T,L/C |

| Delivery Time: | 10-15 days |

| Shipping Port | Tianjin/Qingdao/Shanghai |

| Certification | ISO2000,SGS |

Technical parameter of our Rotary Drum Granulator:

| Spe. | Shell | Cap-acity | Motor | Reducer | Size | Wei- ght |

|||||

| ID mm | L mm |

Slope ° | Rev. r/min | t/h | Model | kw |

Model | Ratio | L×W×H | Ton | |

| φ0.8×3.2 | 800 | 3200 | 2.5 | 17 | 2.5 | Y132M1 -6 |

4 | JZQ350 | 15.75 | 3800× 1800× 2000 |

5.5 |

| φ1.2×3.5 | 1200 | 3500 | 2.5 | 18.07 | 3 | Y160M -6 |

7.5 | JZQ500 | 12.5 | 3960× 3070× 2129 |

7 |

| φ1.4×4 | 1400 | 4000 | 2.5 | 15.05 | 5 | Y160M -4 |

11 | JZQ500 | 20.49 | 4400× 2810× 2600 |

8 |

| φ1.5×5 | 1500 | 5000 | 2.5 | 12.6 | 6 | Y180L -6 |

15 | ZQ500 | 12.64 | 5400× 2910× 2800 |

10 |

| φ1.6×6 | 1600 | 6000 | 2.5 | 12 | 7 | Y180L -6 |

15 | ZQ500 | 12.64 | 7700× 3003× 3216 |

11 |

| φ1.8×6 | 1800 | 6000 | 2.5 | 11.5 | 8 | Y180L -6 |

15 | ZQ650 | 10.35 | 8000× 3335× 3350 |

16 |

| φ1.8×8 | 1800 | 8000 | 2.5 | 11.5 | 10 | Y180L -6 |

15 | ZQ650 | 10.35 | 10000× 3380× 3350 |

18 |

| φ2.0×7 | 2000 | 7000 | 2.5 | 10.8 | 14 | Y225M -6 |

30 | ZQ650 | 10.35 | 11000× 3900× 3750 |

25 |

| φ2.2×8 | 2200 | 8000 | 2.5 | 10.85 | 20 | Y250M -6 |

37 | ZQ650 | 12.64 | 9500× 4410× 3900 |

29 |

| φ2.4×10 | 2400 | 10000 | 2.5 | 9.6 | 25 | Y250M -4 |

55 | ZL75 | 20 | 11600× 4636× 4955 |

42 |

| φ2.6×10 | 2600 | 10000 | 2 | 9.17 | 30 | Y315M -6 |

90 | ZL75 | 14 | 12200× 4850× 4262 |

52 |

| φ2.8×10 | 2800 | 10000 | 2 | 8.35 | 35 | Y315M -6 |

90 | ZLY315 | 14 | 12000× 5300× 5200 |

60 |

| φ2.9×6 | 2900 | 6000 | 1.8 | 9.46 | 40 | Y315M2 -6 |

132 | ZL85 | 14 | 9000× 5400× 5800 |

68 |

| φ3.0×9 | 3000 | 9000 | 1.8 | 9.06 | 45 | Y315L1 -4 |

160 | ZLY355 | 20 | 1100× 6000× 5800 |

70 |

| φ3.2×10 | 3200 | 10000 | 1.8 | 8.54 | 50 | Y315L1 -4 |

160 | ZL100 | 20 | 12100× 5050× 5800 |

80 |

| φ3.3×9 | 3300 | 9000 | 2.5 | 9.14 | 55 | Y315L2 -4 |

200 | ZLY400 | 20 | 12500× 6689× 6399 |

85 |

| φ3.5×8 | 3500 | 8000 | 2.5 | 9.25 | 56 | Y315L2 -4 |

200 | ZLY400 | 20 | 10000× 6800× 7000 |

93 |

Application of Rotary Drum Granulator

Winnermac Rotary Drum Granulator as one of the key equipments in fertilizer industry, The cylinder body adopts special stainless steel or rubber plate lining structure. It can remove scar and peel burl automatically It has the advantages of high intensity of granule, high production, erosion proof, abrasion proof, low energy consumption, long service life, convenient operation and maintenance etc. Remark: If the formulation, process and raw material are different, it will affect the yield, grain rate and the diameter of the grain.

Advantages of Rotary Drum Granulator

1.The barrel body of this rotary drum granulator is made up of special rubber plate lining or acid-resistant stainless steel lining plate, thus automatic scar and burl removal is achieved. So the traditional scraper device is canceled in this rotary drum granulator.

2.This granulator features an attractive appearance, rational structure, high granulating intensity, good corrosive resistance, good abrasive resistance, low energy consumption, long service life, convenient operation and easy maintenance, etc.

3.This granulator is applicable to producing both of organic and inorganic fertilizers.

Working Principle of Rotary Drum Granulator :

Raw materials to be granulated can be steam, gaseous ammonia, phosphoric acid, ammoniacal solution, ammonium phosphate slurry, and triple superphosphate slurry. After these solid fertilizer particles enter into the rotary drum, they will make reciprocating movement under functions of gravity, centrifugal force, and friction force between fertilizers. With the rotary movement of the drum, produced materials spray onto the surface of granulation nucleus. Then the coating layers become thicker and thicker until produced materials are granulated into required dimensions. Finally, those obtained products are spilled out from the discharging hole.

Where could we utilize a rotary drum granulator?

A rotary drum granulator, a kind of fertilizer equipment, is mainly used to complete granulation process during compound fertilizer production processes.

Firstly, add raw materials into the drum. Then the materials will rotate along with drum rotation. Finally, the materials will form into granules under the condition that a certain humidity and temperature is provided.

Note: When our rotary granulator is used for fertilizer production, the raw materials for producing compound fertilizer will finish chemical reaction and heat generation inside the drum. Compound fertilizer raw material may include vapor, ammonia gas, phosphoric acid or nitrogen solutions, phosphorus and ammonia slurry, and TSP slurry, etc.

Why choose our rotary drum granulator?

1. Granulation rate reaches 70%. A few bit of reverts with small granularity are available for new granulation.

2. By adopting vapor for material heating, finished granules feature low water content. Thus the load of drier is reduced and production efficiency is improved.

3. UHMW-PE inner drum lining features good corrosion resistance and heat preservation capability. It can effectively prevent raw materials from sticking to the drum. Therefore, our rotary granulator can help reduce labor intensity and prolong machinery lifetime.

4. Our rotary drum granulator features simple operation, large production, low power consumption and low maintenance cost.

Our Company is a professional manufacturer and supplier of fertilizer Machine, formula fertilizer blending machinery, fertilizer mixing machine and soluble fertilizer machine, and automatic production line for fertilizer, we also have many other products, such as Micro element compound fertilizer Production line and organic fertilizer production line.

Our products not only cover the domestic market but also are exported to other countries such as Korea, North Korea, and Kazakhstan etc. Moreover, we have received good comments from both home and abroad. The products have established a splendid brand image in both society and customers, and have been reported on many newspapers. As a famous enterprise, our corporation was the first corporation that has passed “ISO9001” among the same industries, as well as a series of state-level tests. Our corporation is a well-known company in the field of fertilizer machine production and also the head in terms of technology and service.We always believe in Customer satisfaction. Our products are known for their quality and durability.

Our products not only cover the domestic market but also are exported to other countries such as Korea, North Korea, and Kazakhstan etc. Moreover, we have received good comments from both home and abroad. The products have established a splendid brand image in both society and customers, and have been reported on many newspapers. As a famous enterprise, our corporation was the first corporation that has passed “ISO9001” among the same industries, as well as a series of state-level tests. Our corporation is a well-known company in the field of fertilizer machine production and also the head in terms of technology and service.We always believe in Customer satisfaction. Our products are known for their quality and durability.

If you are interested, please do not hesitate to contact me for more information, and at the same time we hope to set up a long-term business relationship with your esteemed company.

OurCooperation/ Exported Countries

※ Indonesia ※

※ Indonesia ※

NPK compound fertilizer production line with capacity 50,000tons per year in 2010

NPK compound fertilizer production line with capacity 20,000tons per year in 2011;

NPK compound fertilizer production line with capacity 100,000tons per year in 2012

Organic fertilizer production line with capacity 50,000tons per year in 2013.

※ Egypt ※

Compound fertilizer production line with capacity 30,000tons per year in 2009

Compound fertilizer production line with capacity 80,000tons per year in 2010;

※ Nigeria ※

Compound fertilizer production line with capacity 30,000tons per year in 2010.

※ Mauritius ※

NPK compound fertilizer production line with capacity 50,000tons per year in 2010,

※ Vietnam ※

Compound fertilizer production line with capacity 20,000tons per year in 2009,

Most of our old clients have purchased or been planning to purchase a second production line to enlarge the manufacturing capacity owing to our good quality and best after-sales service .We have been relying on high-quality products, advanced technology, reasonable price, and good after-sales service to meet the requirements of all the users.

Why choose us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Winnermac Mining Machinery Manufactory are made by ourselves, with lower price, good quality.

2. Full and perfect service

♥.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design

and manufacturer equipment according to your special demand.

♥.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you

♥.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

3. Product Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc.

4. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demand.

Over 26 years experience in this field

belt conveyor,bucket elevator,screw conveyor,vibrating feeder,vibrating screen,rotary screen,etc.